In today's highly precise and rapidly iterating industrial fields, Custom mechanical parts have become a key force in promoting technological innovation and industrial upgrading. From tiny gears in precision medical equipment to large structural parts in heavy industrial machinery, Custom mechanical parts meet the urgent needs of all walks of life for efficient, precise and durable parts with their unique design flexibility and performance.

The core advantage of Custom mechanical parts lies in their design flexibility. Unlike traditional standard parts, customized parts can be fully customized according to the specific needs of customers, from material selection, size specifications to functional characteristics. This feature enables designers to break through conventional limitations and create mechanical parts that meet the requirements of specific application scenarios and have innovative design concepts. In the field of aerospace, customized high-temperature alloy parts can withstand high temperatures and high pressures in extreme environments to ensure the safe and stable operation of aircraft.

With the rapid development of computer-aided design (CAD) and computer-aided engineering (CAE) technology, the design process of Custom mechanical parts has become more efficient and precise. Designers can use these software to perform complex 3D modeling, simulation analysis, and even predict the performance of components in a virtual environment, thereby optimizing the structure, reducing material waste, and improving overall efficiency during the design phase.

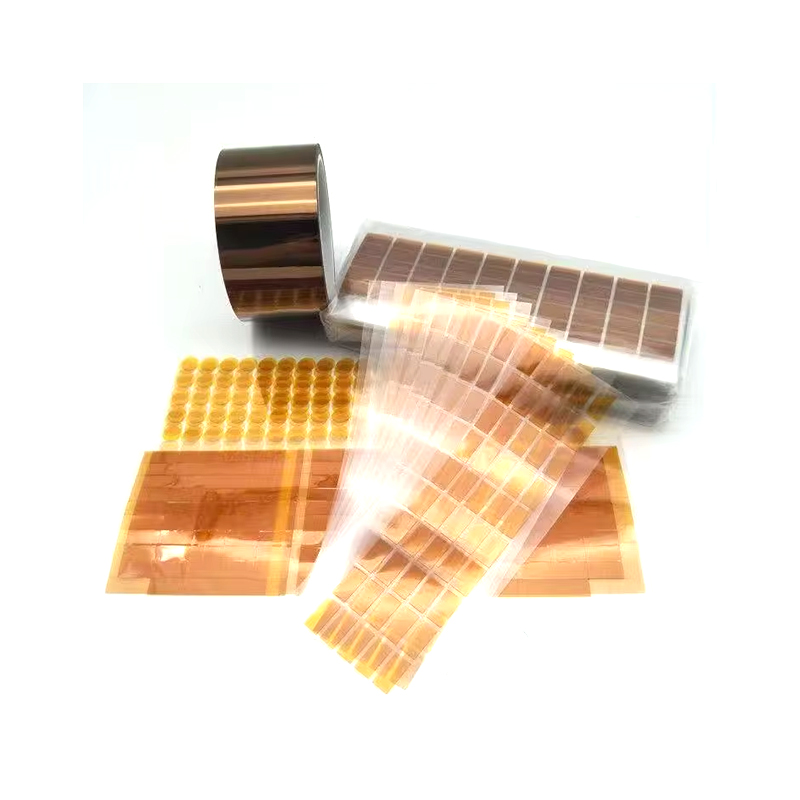

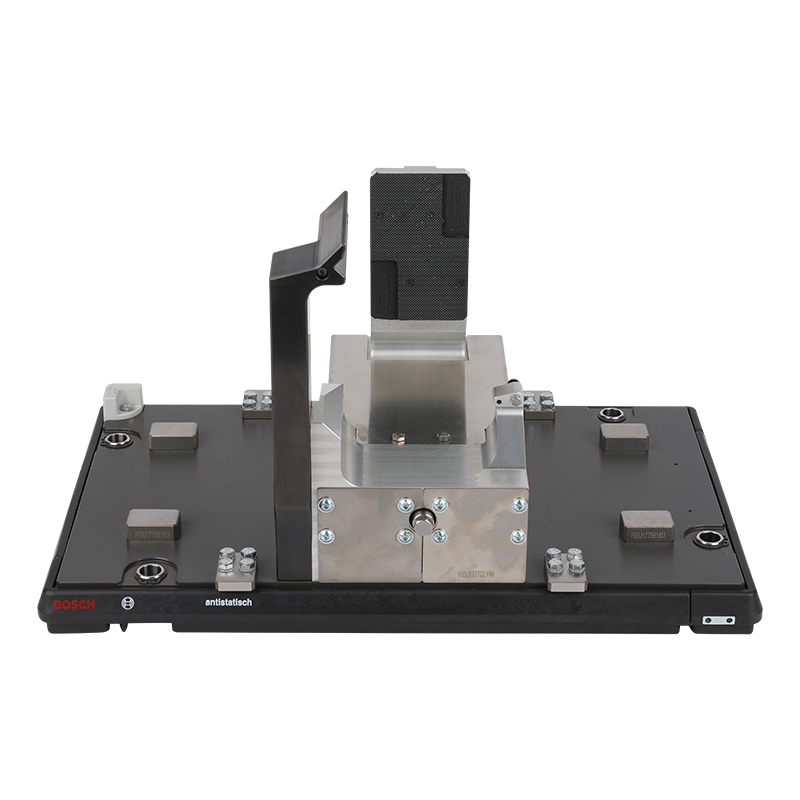

The manufacture of Custom mechanical parts also reflects the progress of modern science and technology. Advanced manufacturing technologies, such as five-axis machining centers, laser cutting, and 3D printing, make it possible to manufacture high-precision, complex structure components. In particular, 3D printing technology, with its rapid prototyping, material diversity, and direct manufacturing capabilities for complex structures, has greatly shortened the product development cycle, reduced the cost of prototyping, and made complex designs that were previously difficult to achieve a reality.

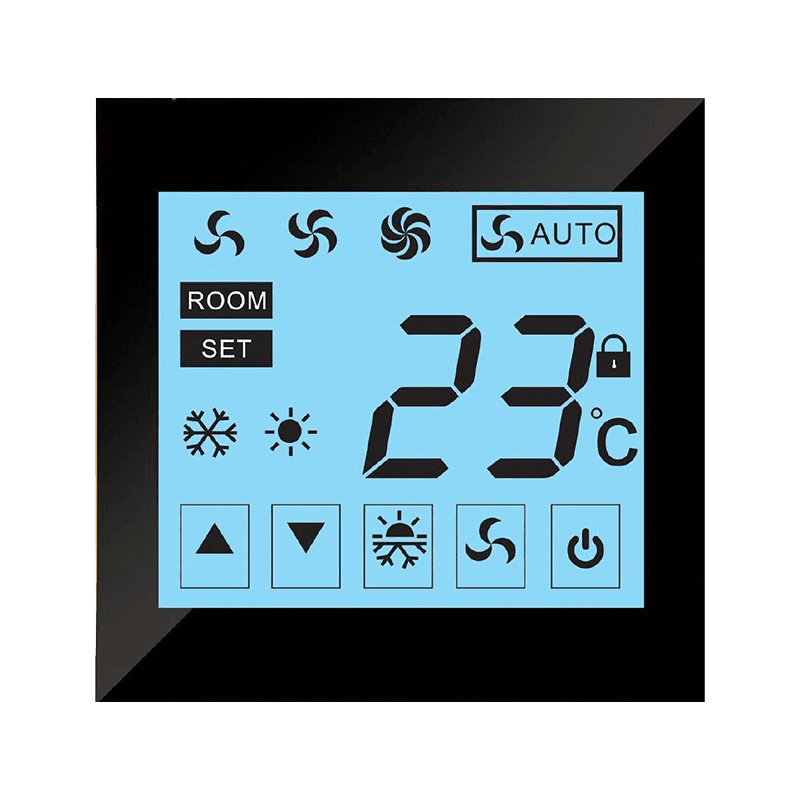

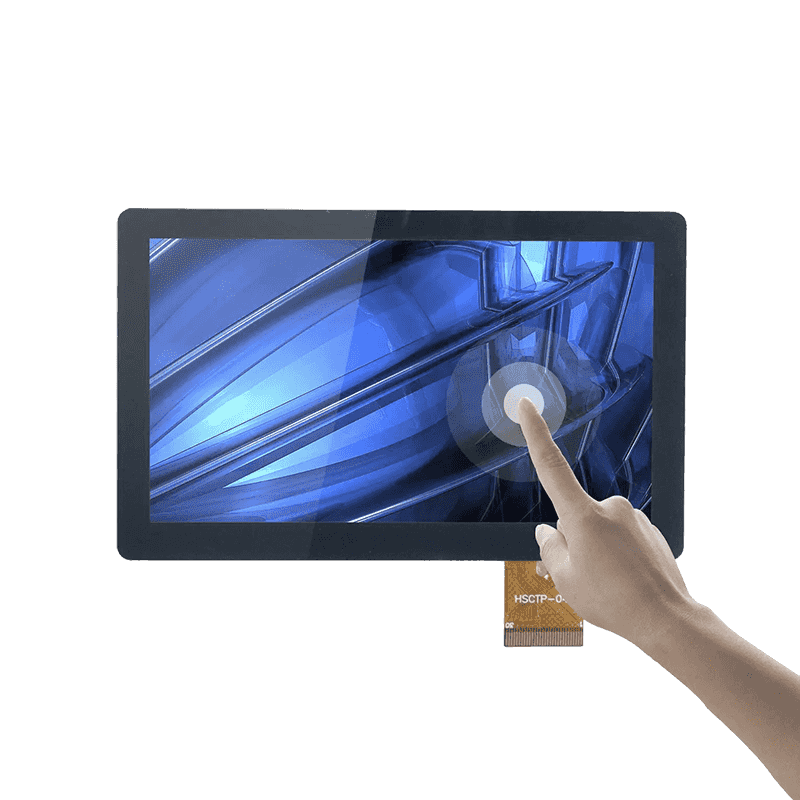

The application range of Custom mechanical parts is wide, covering almost all industries that require precision mechanical systems. In medical equipment, customized precision parts ensure the accuracy and reliability of surgical instruments; in the field of new energy vehicles, high-performance customized parts improve the efficiency and safety of battery management systems and drive systems; on automated production lines, customized robotic arms and sensors greatly improve production efficiency and flexibility.

English

English русский

русский