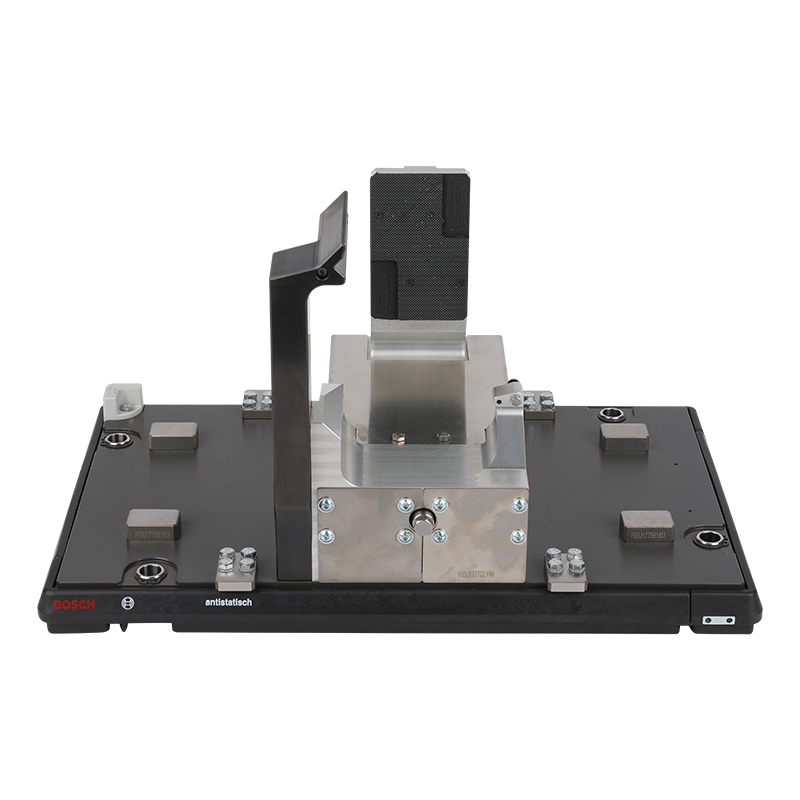

In the ever-changing modern manufacturing industry, customized CNC (computer numerical control) machining is gradually becoming the core force to promote industry innovation and development with its high precision, high efficiency and flexibility. CNC machining technology controls machine tools through computer programs to achieve the machining of parts with complex shapes and precise dimensions, providing unprecedented customized solutions for all walks of life.

Core advantages of customized CNC machining

**1. High precision and high quality

Customized CNC machining uses advanced software and precision machine tools to ensure that the dimensional accuracy of machined parts reaches the micron level or even the nanometer level. This high precision not only meets the needs of high-demand industries such as aerospace and medical devices, but also promotes quality upgrades in the fields of automotive manufacturing and electronic equipment.

**2. Efficient production

Compared with traditional manual machining or simple mechanical machining, CNC machining has greatly improved production efficiency through automated operations. Once the program is set, the machine tool can perform machining continuously and stably, reducing human intervention, shortening the production cycle and reducing costs.

**3. Flexibility and diversity

The greatest charm of customized CNC machining lies in its flexibility. Whether it is a complex three-dimensional surface or a tiny internal structure, it can be easily achieved by adjusting the program. This ability enables CNC machining to respond quickly to market changes, meet customers' personalized needs, and promote product innovation.

Wide coverage of application fields

**1. Aerospace

In the field of aerospace, customized CNC machining is widely used in the manufacture of engine components, structural parts and precision instruments. These components often require extremely high strength and lightweight design, and CNC machining technology can ensure the stability and reliability of parts in complex environments.

**2. Medical devices

The manufacture of medical devices has extremely high requirements for precision and material properties. Customized CNC machining can accurately manufacture surgical instruments, implants, etc. to ensure their safety and effectiveness during medical procedures.

**3. Automobile manufacturing

With the development of electric vehicles and intelligent driving technology, automobile manufacturing has increasingly higher requirements for the precision and complexity of parts. Customized CNC machining not only improves the performance of core components such as engines and gearboxes, but also promotes lightweight design of the body and improves the energy efficiency and safety of the entire vehicle.

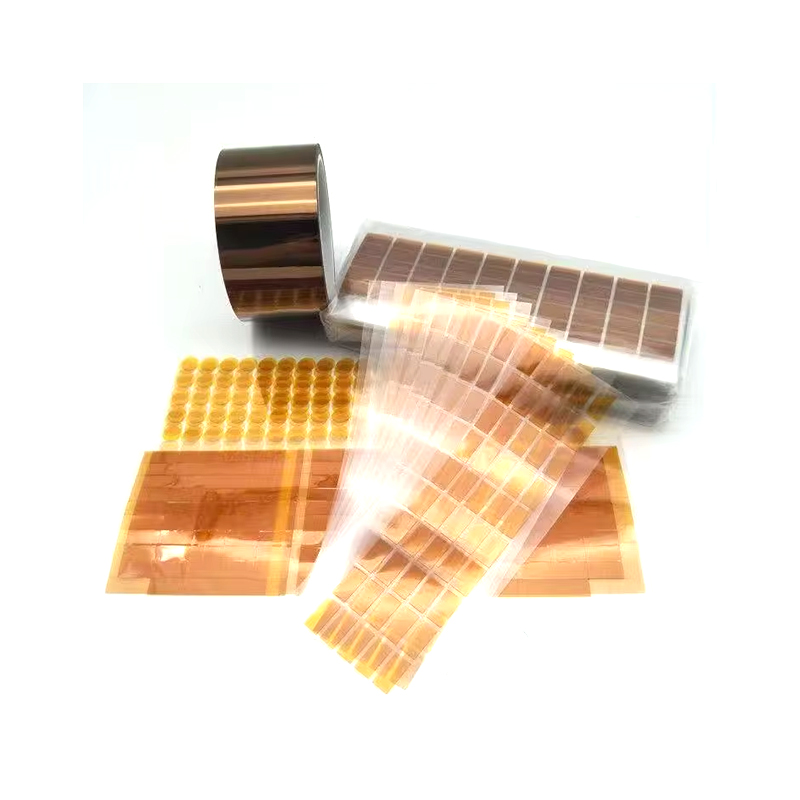

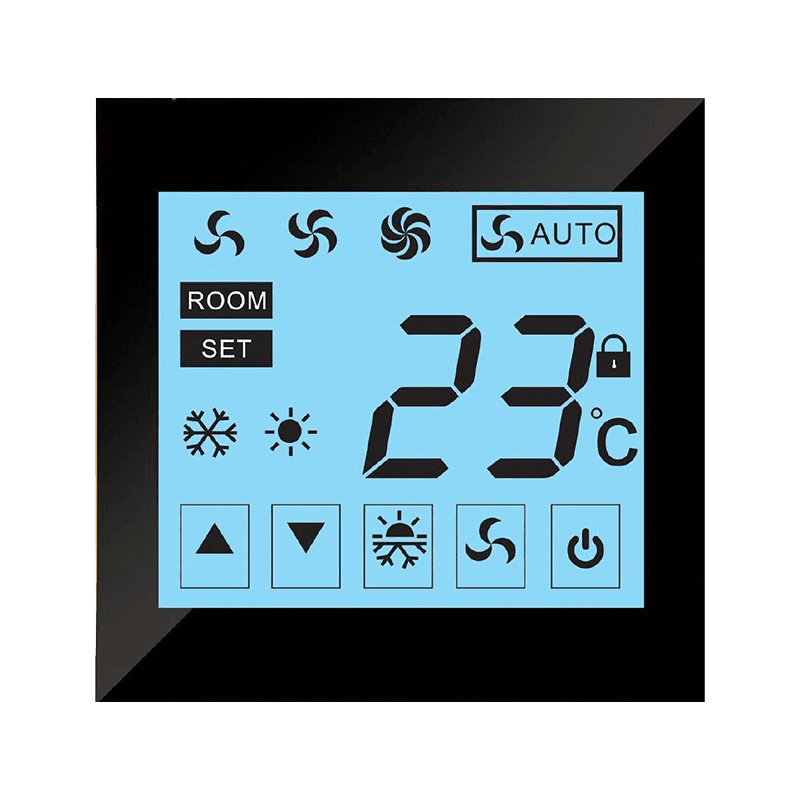

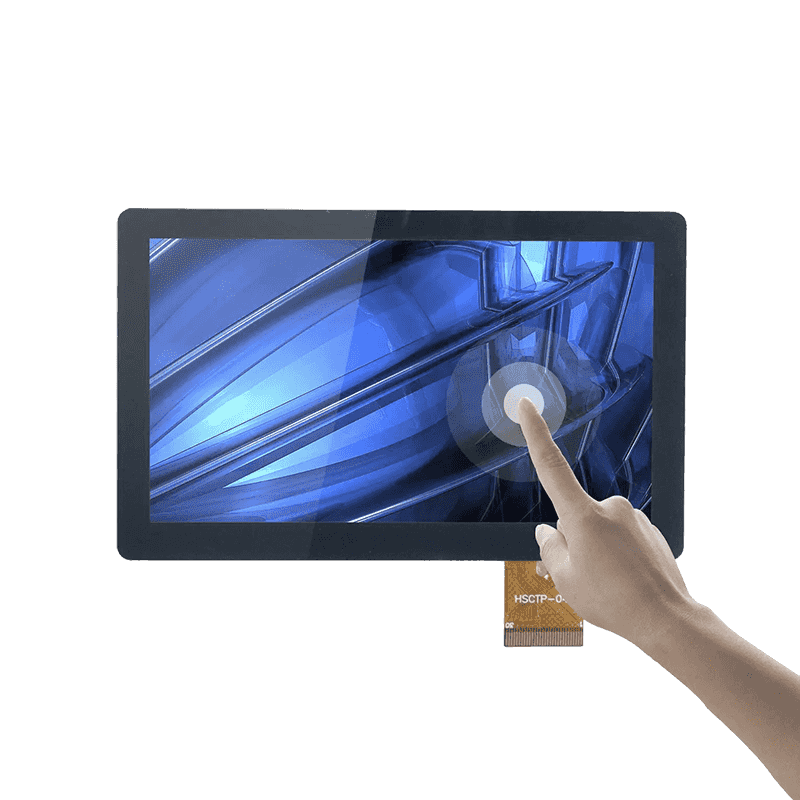

**4. Consumer electronics

Smartphones, tablet computers and other consumer electronics products are updated and replaced at a very fast speed. Customized CNC processing can quickly respond to design changes and achieve high-precision processing of shells, internal structural parts, etc., meeting consumers' dual pursuit of product appearance and performance.

With the integration of technologies such as artificial intelligence and the Internet of Things, customized CNC processing will move towards a new stage of greater intelligence and networking. Intelligent CNC machine tools can autonomously learn and optimize processing parameters to achieve more efficient and more accurate processing. At the same time, through the cloud platform, customers can remotely monitor production progress, achieve on-demand customization and instant delivery, further shorten the supply chain cycle, and enhance market competitiveness.

English

English русский

русский