As a key link between production and consumption, the efficiency and accuracy of logistics and transportation are directly related to the competitiveness of the entire supply chain. With the rapid development of science and technology, customized automation equipment is penetrating into the field of logistics and transportation at an unprecedented speed, leading a profound industry change with its precise and efficient characteristics.

The core of automation technology lies in the automation control and management of production or transportation processes through the high integration of electronics, machinery, computers and information technology. In the field of logistics and transportation, the application of this technology not only greatly improves the operating efficiency, but also significantly reduces human errors and ensures the safety and accuracy of cargo transportation. From simple cargo sorting to complex warehouse management, automation equipment is gradually replacing traditional manual operations and becoming the new favorite of the logistics industry.

Faced with the increasingly complex and changing needs in the field of logistics and transportation, customized automation equipment has emerged. Unlike standardized products, customized equipment can be personalized designed and manufactured according to the specific needs of the enterprise, such as warehouse layout, cargo characteristics, transportation routes and other factors. This "tailor-made" service model not only improves the applicability and efficiency of the equipment, but also helps enterprises to achieve precise control of logistics costs and enhance market competitiveness.

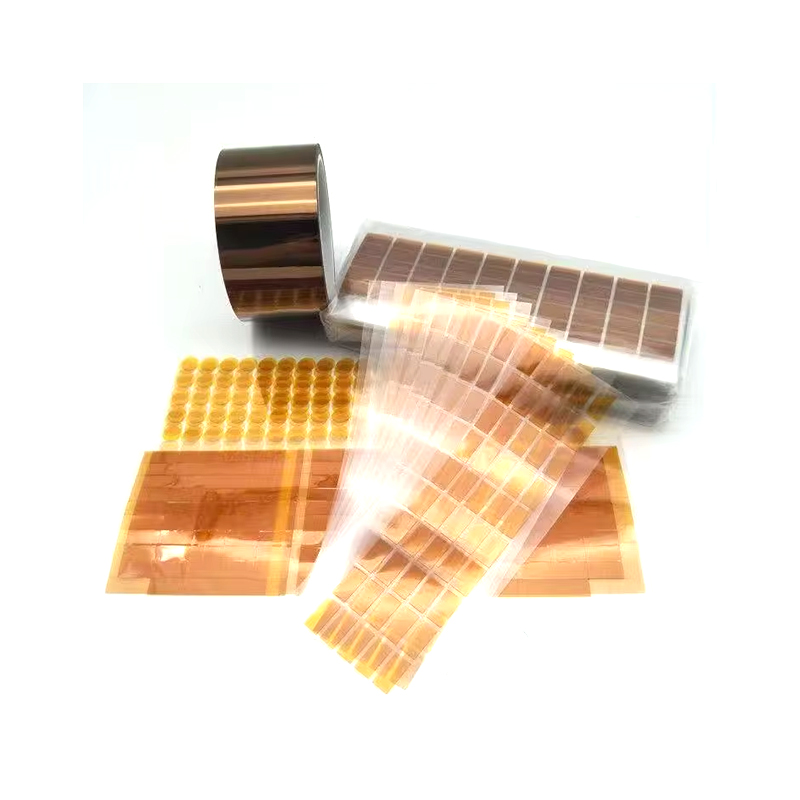

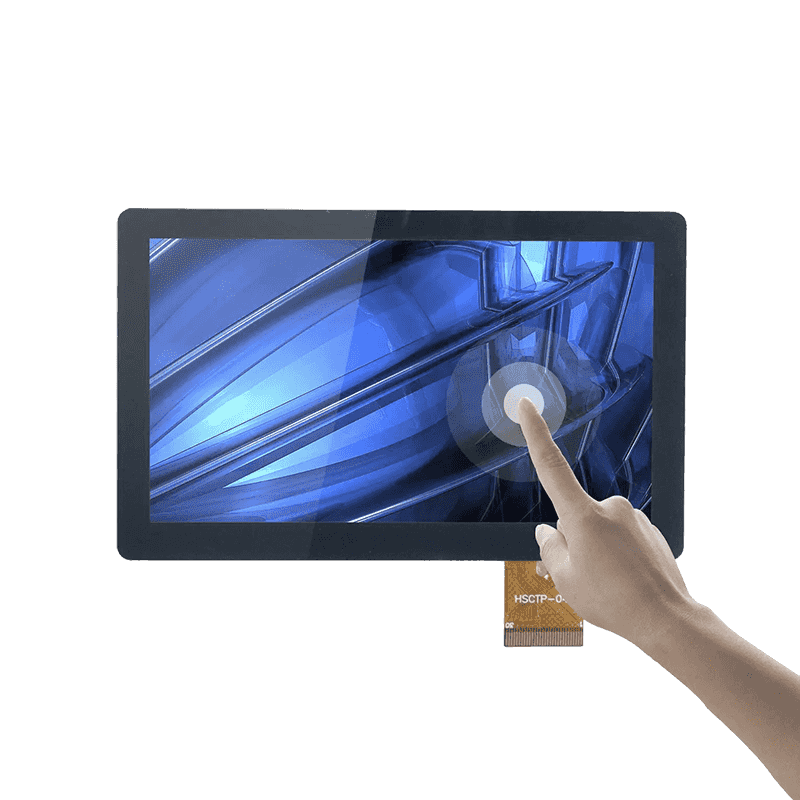

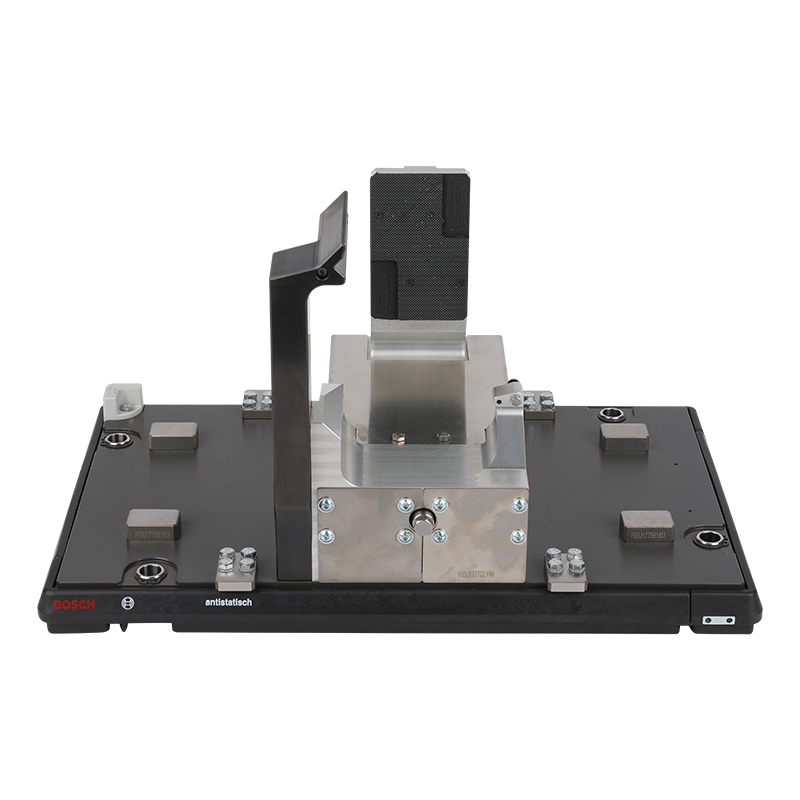

Among the many links in logistics and transportation, sorting operations are a crucial link. Traditional manual sorting is not only inefficient, but also prone to errors. The customized automated sorting system integrates advanced identification technologies (such as RFID, barcode scanning), high-speed robotic arms and intelligent algorithms to achieve efficient and accurate classification and sorting of goods. These systems can work 24 hours a day, greatly improving the sorting speed, while reducing the error rate, and winning valuable time and cost advantages for logistics companies.

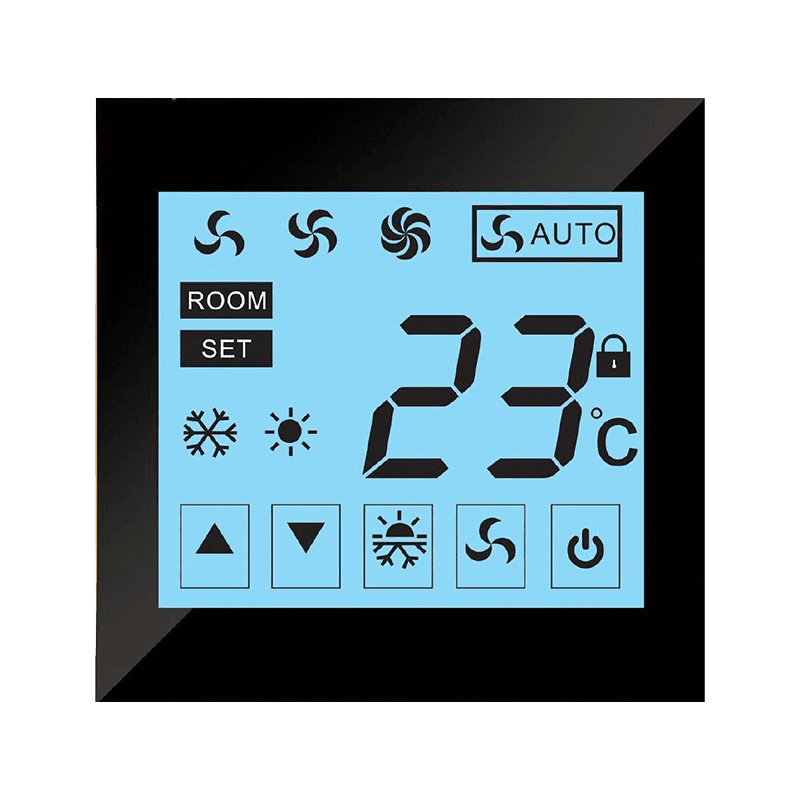

Warehouse management is an important part of logistics and transportation. Customized intelligent warehousing systems maximize the use of warehouse space and improve the efficiency of goods storage and retrieval by introducing advanced equipment such as automated stereoscopic warehouses and AGVs (automatic guided vehicles). These systems can automatically plan storage locations, optimize cargo layout, reduce the number of handling times, and improve storage density and access efficiency based on factors such as the type, quantity, and storage period of the goods.

With the increasing maturity of autonomous driving technology, the application of unmanned transport vehicles in the field of logistics and transportation has gradually become a reality. Customized unmanned transport vehicles can not only drive autonomously in complex road environments, but also be intelligently dispatched according to real-time road conditions and cargo demand to achieve fast and safe transportation of goods. The application of this technology will further reduce the labor cost of logistics and transportation, improve transportation efficiency, and bring unprecedented changes to the logistics industry.

The innovative application of customized automation equipment in the field of logistics and transportation is the inevitable result of scientific and technological progress and industrial upgrading. With its precise and efficient characteristics, it not only improves the efficiency and accuracy of logistics and transportation, but also promotes the intelligent and automated transformation of the entire logistics industry.

English

English русский

русский